PRODUCTION METHODS

ACL has an array of varied and efficient machinery to provide qualitative solutions to your requests, whichever metal building material you require (Steel, Stainless steel, aluminium).

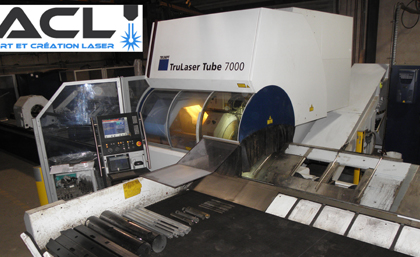

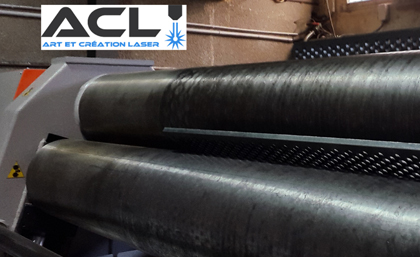

We use Flatbed sheet metal laser cutting, tube/profile laser cutting, numerical punching, sheet metal bending (with a wide range of Press-Brakes) and also Roll bending.

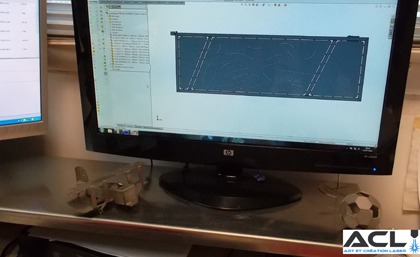

From a software point of view, we are equipped with Solidworks, Tube Design and Tru Tops and are able to accept the following file types: dxf, dwg, IGES and STEP.

ACL is there to assist and guide you, from the initial design stage right through to the creation of your projects.